Precision. Performance. Perfection.

Quality

Quality Assurance – Sherence India

At Sherence India, quality is not just a part of our process — it’s the foundation of everything we do. We are committed to delivering premium-quality brass components and fittings that exceed customer expectations in performance, durability, and safety.

From raw material sourcing to final dispatch, every stage of production is governed by strict quality control standards. Our dedicated QA team conducts multi-level inspections and precision testing to ensure that each product meets national and international benchmarks.

Our Quality Commitments

High-Grade Raw Materials: We source certified brass and metal alloys to ensure strength, reliability, and corrosion resistance.

Precision Manufacturing: All components are produced using advanced CNC machines, threading tools, and molding systems for accuracy and consistency.

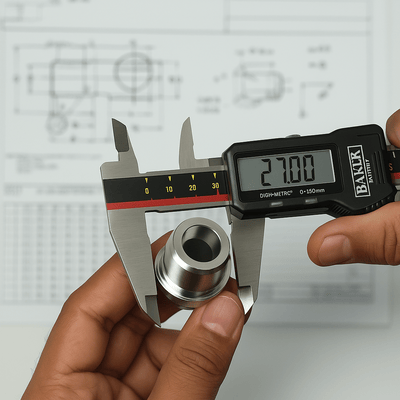

Multi-Stage Inspection: Every batch undergoes dimensional checks, pressure tests, threading accuracy checks, and surface finish verification.

Compliance & Standards: Products are manufactured in accordance with ISO standards and customer-specific technical requirements.

Continuous Improvement: We adopt Kaizen and Lean practices to consistently enhance quality, efficiency, and customer satisfaction.

Our Quality Commitments

High-Grade Raw Materials: We source certified brass and metal alloys to ensure strength, reliability, and corrosion resistance.

Precision Manufacturing: All components are produced using advanced CNC machines, threading tools, and molding systems for accuracy and consistency.

Multi-Stage Inspection: Every batch undergoes dimensional checks, pressure tests, threading accuracy checks, and surface finish verification.

Compliance & Standards: Products are manufactured in accordance with ISO standards and customer-specific technical requirements.

Continuous Improvement: We adopt Kaizen and Lean practices to consistently enhance quality, efficiency, and customer satisfaction.

Why Sherence India Stands Out

In-house testing and inspection facility

Use of calibrated gauges and instruments

Highly trained quality assurance professionals

Commitment to zero-defect manufacturing

Transparent documentation and full traceability of batches

Focus on customer feedback and continual upgrades